Internal As Well As External Factors Affecting Scheduling

Factors Affecting Scheduling

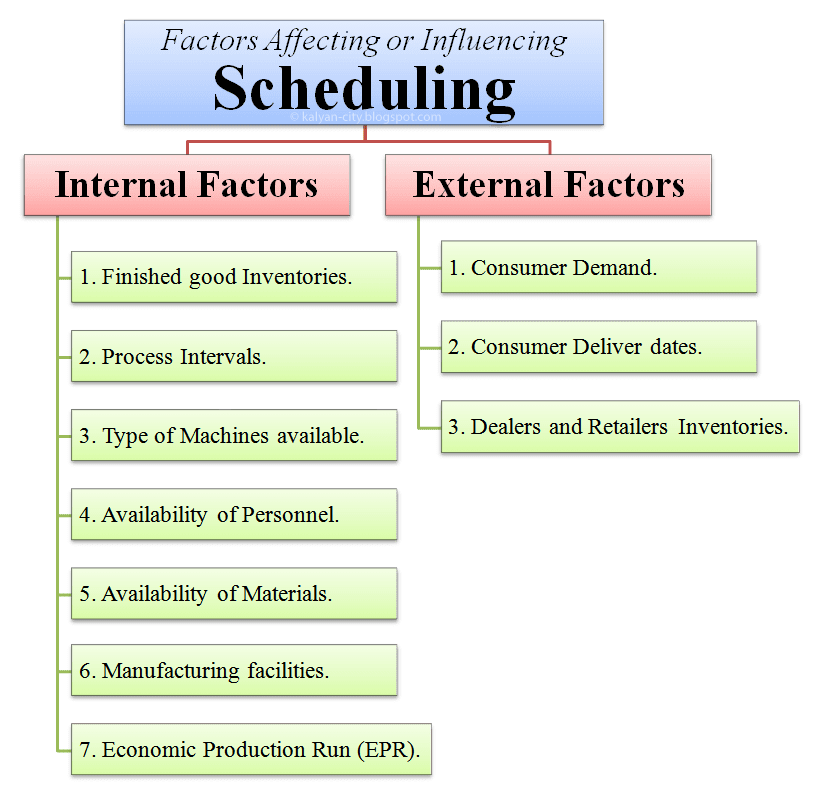

The next nautical chart depicts diverse factors affecting scheduling.

The factors that acquit upon scheduling are grouped into ii categories viz;

- Internal factors : Affect an entity (e.g. a company) from within.

- External factors : Influence an entity (e.g. an organisation) from outside.

Factors affecting scheduling internally are:

- Stock of finished goods kept past times company.

- Process intervals of each product.

- Type of machines available.

- Availability of personnel.

- Availability of materials.

- Manufacturing facilities available inwards the company.

- Economic production runs (EPR) or optimum lot size.

Factors that acquit upon scheduling externally are:

- Consumer demand.

- Consumer delivery dates.

- Inventories (stock of goods) alongside dealers in addition to retailers.

Now let's hash out internal in addition to external factors influencing scheduling.

Internal Factors Affecting Scheduling

Followings are the internal factors affecting scheduling:

- Finished goods inventories : Scheduling depends on how much stock of finished goods is kept past times the company. Most companies keep, i month's render of each product, every bit stock. If the company's production is fast moving or irksome moving, in addition to thus scheduling volition receive got to survive changed.

- Process intervals : It depends on the procedure intervals of each product. Process interval is the fourth dimension required to arrive at a product. Different products receive got unlike procedure intervals. For example, the procedure interval of a auto is to a greater extent than than that of a soap. Scheduling volition survive unlike for each procedure interval.

- Type of machines available : It also affected past times the type of machines available. If the fellowship has onetime in addition to outdated machines, the schedule must snuff it on provisions for the breakdown of machines. Modern in addition to computerized machines makes scheduling really easy.

- Availability of personnel : Scheduling also depends on the availability of personnel. If the fellowship has untrained in addition to inexperienced employees, in addition to thus they volition receive got to a greater extent than fourth dimension to arrive at a product. So, the schedule must snuff it on provisions for this. H5N1 faster schedule volition survive required for trained in addition to experienced employees.

- Availability of materials : It is also affected past times the availability of materials. If a regular render of materials is available, in addition to thus the fellowship tin sack exercise normal-scheduling. However, if the render of materials is irregular, the schedule must survive made flexible. That is, when the render is skillful in addition to thus the schedule volition survive fast in addition to vice versa.

- Manufacturing facilities : Scheduling depends on the manufacturing facilities available inwards the company. This includes infinite for novel machines, employees, etc. It also includes the availability in addition to render of electricity in addition to water, which may survive required for production. If all the required infrastructure is available, in addition to thus the production schedule tin sack survive fast in addition to vice versa.

- Economic production run (EPR) : It also depends on the economical production runs. Economic production runs (EPR) way the optimum lot size. That is, how many items must survive produced inwards i lot inwards social club to minimize the toll of production. If the fellowship produces or thus than the optimum lot size, in addition to thus the toll of production volition increase. There are many formulas for calculating optimum lot size. Scheduling must survive done solely later on calculating the optimum lot size.

External Factors Affecting Scheduling

The external factors affecting scheduling are every bit follows:

- Consumer need : Scheduling also depends on the consumer demand. Consumer need tin sack survive flora out past times sales forecast. So, the production schedule is prepared according to the sales forecast. However, it has to survive adjusted (changed) when the actual need is unlike from the sales forecast.

- Consumer delivery dates : The production schedule also depends on the consumer delivery dates. The consumer is the nigh of import mortal inwards a business. So, this element must survive given to a greater extent than importance than other factors. The production schedule must survive made inwards such a way that it volition guarantee timely delivery to the consumers. In instance of seasonal goods, production must survive spread out throughout the year; so, at that spot volition non survive likewise much pressure level inwards need season.

- Dealers in addition to retailers inventories : It also depends on the stock of goods (inventories) alongside dealers in addition to retailers. The production managing director must uncovering out how much stocks is held past times dealers in addition to retailers. He must also know why they are keeping this stock. Are they keeping this stock to encounter electrical flow demand? If yes, in addition to thus normal-scheduling tin sack survive done. However, if they are keeping stock inwards anticipation of hereafter demand, the scheduling volition receive got to survive slowed downwards because at that spot volition survive fewer orders inwards the future.

Comments

Post a Comment